|

|

| |

| |

|

|

|

| |

| |

|

These tracks are equipped with sidewalls that act as paddles, creating mechanical anchoring and preventing slippage on the ground. This enables movement across all types of terrain, including the ability to cross lakes and rivers.

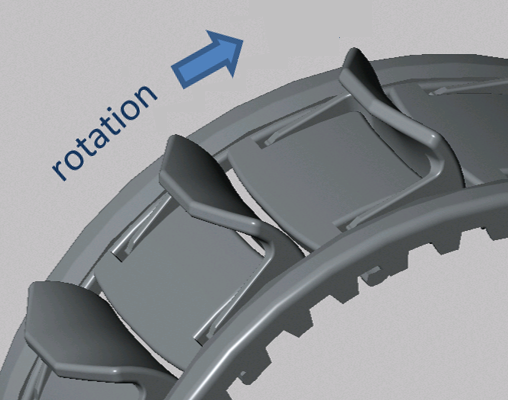

The innovation lies in the retractable paddles: on hard ground, they retract and the track behaves like a conventional one; on soft terrain, they automatically deploy.

|

| Amphibious Elastomer Track Prototype |

Paddle deployment can be manually controlled by the operator, managed by an onboard computer (AI), or triggered automatically via a spring mechanism whose force is inversely proportional to terrain hardness. On solid ground, the spring remains inactive; on muddy terrain, it partially engages; and in water, it fully activates.

A vehicle equipped with such tracks moves effortlessly across solid ground, mud, and marshy environments. It can travel swiftly over water, overcome submerged obstacles, and land without concern for ground conditions.

All track types are compatible: metallic link tracks, elastomer belts, or semi-metallic hybrids.

Target markets include military vehicles (from small drones to heavy tanks), construction equipment, agricultural machinery, recreational vehicles, and toys.

Features of the First Functional Model

|

|

The paddles have unique geometric properties: 1. They pivot around an axis located near the outer surface of the track, minimizing torque from granular or liquid media that might otherwise cause unwanted deployment or retraction. 2. They are forward-concave, generating diffuse lift beneath the track. 3. Their shape is curvilinear, resembling an inverted turbine blade: - The upper section (near the rolling plane) has a gentle slope for smooth contact with sand, minimal disturbance, and good stability. - The lower section (deeper in sand, mud, or water) has a steeper angle, producing an oblique reaction (rearward and slightly upward), ensuring effective traction and progressive lift. The angle of attack can be adjusted by controlling the deployment level. 5. Their edges are angled laterally to encourage retraction under side forces, while the central portion remains horizontal to allow lateral sliding during turns. 6. A push mechanism opposite the paddle’s pivot axis enables forced retraction—both at the top of the track and when rotating around the rear sprocket or roller—preventing unnecessary energy loss from lifting ambient material. 7. Conversely, the paddle remains deployed when rotating around the front sprocket or roller to maximize lift |

At the lower end, the rubber’s elasticity promotes paddle deployment when conditions allow.

Deployment is inversely proportional to ground hardness: compact sand or fine gravel limits deployment, keeping paddles more vertical for optimal traction; very loose sand allows greater deployment and tilt, improving traction while reducing sinkage.